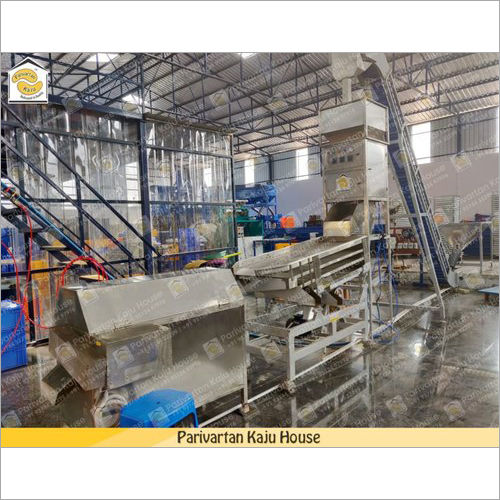

Full Automatic Cashew Nut Processing Plant

उत्पाद विवरण:

- शर्त

- मटेरियल Stainless Steel & Mild Steel

- रेटेड फ़्रिक्वेंसी हर्ट्ज (एचजेड)

- वोल्टेज वोल्ट (v)

- प्रॉडक्ट टाइप Full Automatic Cashew Nut Processing Plant

- फंक्शन Complete Cashew Nut Processing (Cleaning, Shelling, Peeling, Grading, Packing)

- एडवांटेज Reduced Labour, Consistent Output, User-Friendly Controls

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- Full Automation, Low Maintenance, High Efficiency

- Reduced Labour, Consistent Output, User-Friendly Controls

- 12 Months

- 30-60 Days

- किलो/घंटा

- हर्ट्ज (एचजेड)

- Industrial Cashew Nut Processing

- हर्ट्ज (एचजेड)

- Stainless Steel & Mild Steel

- Full Automatic Cashew Nut Processing Plant

- वोल्ट (v)

- Complete Cashew Nut Processing (Cleaning, Shelling, Peeling, Grading, Packing)

व्यापार सूचना

- ,

- , , ,

उत्पाद विवरण

We provide Fully Automated Cashew Processing Plants that reduce the need for manpower while ensuring high-qualityoutput.

Core Features & Benefits

Parivartan Cashew Machineryis a leader in manufacturingfull automatic cashew processing plant setups, offering a capacity range of4MT to 100MT of raw cashew nut processing per shift. These setups deliver unmatched efficiency, quality, and productivity. Withfully automated systems, our plants allow businesses to drastically enhance output while maintainingconsistent product quality. The automation process is particularly effective inshell removal, reducing wastage and increasing the yield of whole kernels.

We prioritize worker safety, and our plants featuremodern, safety-conscious equipmentthat minimizes the risk of injury. Ourcost-saving designsincorporateoptimized energy usageand reduce the need for manual labor, creating an efficient, streamlined workflow. Additionally, theeasy-to-operate machineryallows staff of any skill level to quickly adapt, enhancing overall productivity.

Our plants ensureminimal hand contactwith materials, which upholds high standards ofhygieneand product quality. Thespace-saving designsof our setups allow for better utilization of factory space, while thehigh-speed processing capabilitiesfurther enhance productivity, enabling businesses to meet increased demand efficiently.

With a focus onenergy efficiency, our plants help reduce operational costs by lowering electricity consumption. They are also designed to below maintenance, ensuring reliable, continuous operation with minimal downtime. Byautomating the processing stages, companies can save significantly on labor costs, leading to substantial long-term savings. Furthermore, thedurability and long lifespanof our equipment ensure a strong return on investment.

AtParivartan Cashew Machinery, ourfull automatic cashew processing plant setupsprovide an all-in-one solution for businesses looking to enhance productivity, quality, and efficiency in cashew processing. With our innovative designs, companies can streamline their operations while delivering top-quality products at lower costs.

Seamless Automation for Cashew Processing

Achieve unmatched efficiency and consistency with a fully automated cashew nut processing plant. This system incorporates advanced PLC-based controls to monitor every stage from cleaning to packing, significantly reducing the need for manual intervention. The automation ensures optimized performance and uniform product quality, even at higher production capacities.

Precision Engineering and Hygiene

Constructed with food-grade, corrosion-resistant materials, this plant is designed to meet strict hygiene and safety standards. The processing line ensures minimal contamination risk and easy maintenance. Adjustable dimensions and modular design accommodate various production needs, making it adaptable for both small and large-scale industrial operations.

Operator-Friendly and Cost-Efficient

Requiring only a small supervisory team, the plant dramatically lowers labor costs while maintaining output through sophisticated yet user-friendly controls. Its high energy efficiency and low maintenance requirements ensure cost-effective, uninterrupted production. All processes run within ambient to controlled temperatures for product safety and quality retention.

FAQs of Full Automatic Cashew Nut Processing Plant:

Q: How is the installation of the Full Automatic Cashew Nut Processing Plant carried out?

A: Installation is performed on-site by the manufacturers skilled technical team, ensuring precise assembly and optimal configuration tailored to your facilitys specifications.Q: What is the typical lead time for delivery and commissioning of the plant?

A: The standard lead time for manufacturing, delivery, and commissioning ranges from 30 to 60 days, depending on plant capacity and customization requirements.Q: Where can this processing plant be installed and by whom is it suited?

A: The plant is suitable for industrial cashew nut processors seeking high-capacity, consistent output. It can be installed in factories and agro-processing units by manufacturers, exporters, or wholesalers across India.Q: What steps are included in the cashew nut processing sequence?

A: The plant handles the complete process: cleaning, cutting, roasting or steaming, shelling, drying, peeling, grading, and packing raw cashews into ready-to-eat products.Q: What are the key benefits of using this fully automatic plant?

A: Key benefits include reduced labor cost, consistent and high-efficiency output, user-friendly PLC controls, energy-saving operation, superior food safety, and minimal maintenance.Q: How much supervision and manpower does the plant require during normal operation?

A: Thanks to full automation, the plant only requires 2 to 4 operators for general oversight and system supervision, significantly cutting down on labor requirements.Q: What is the processing capacity of this plant, and can it be customized?

A: The plants capacity ranges from 500 kg/hr up to 2 tons per hour (TPH) and its length, height, and other dimensions can be customized as per the operational needs of your facility.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें